When you acquire via web links on our posts, Future and its submission companions might make a payment.

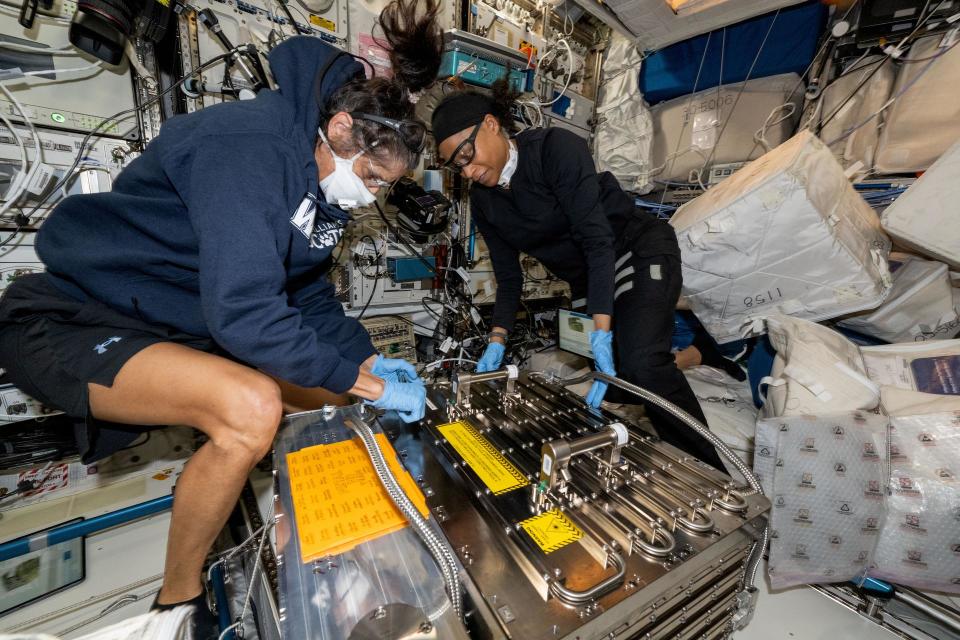

ESA researchers have actually effectively shown 3D printing of a steel component precede for the very first time.

3D printing precede positions obstacles, as several techniques depend on gravity to place products throughout the printing procedure. This is since when producing metal frameworks, liquified steel is frequently made use of as component of the filament, or tool. In space, its actions can be unforeseeable, which can lead to poor-quality things, as the filament may move or be positioned improperly because of the absence of gravitational pressures.

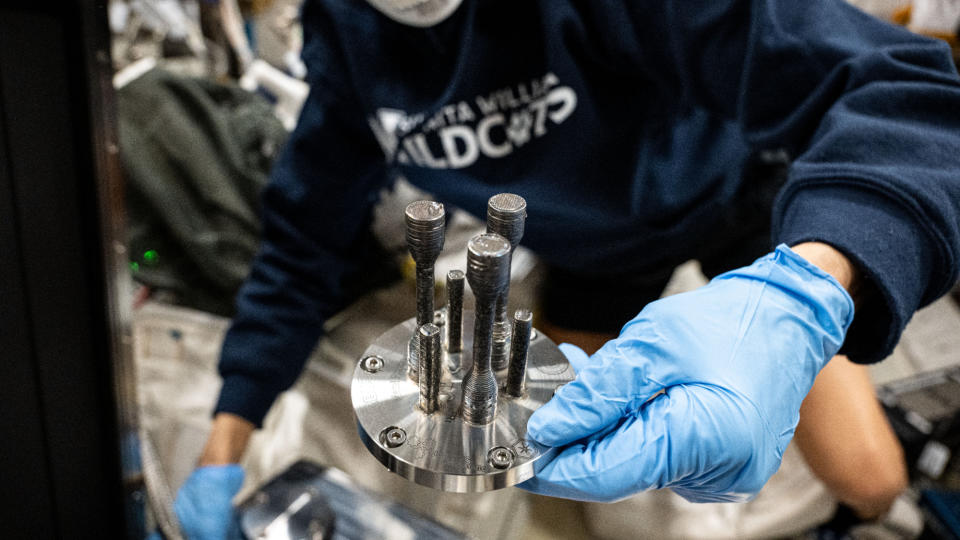

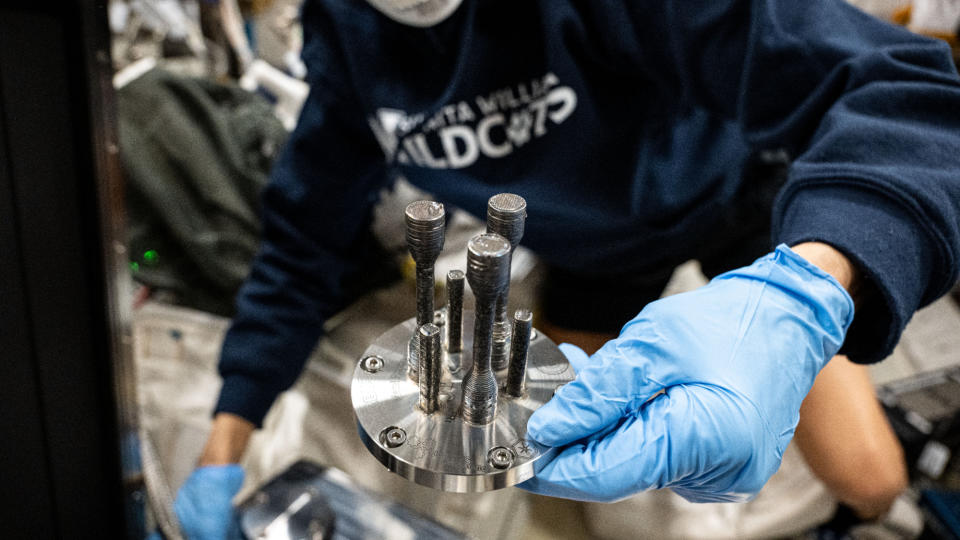

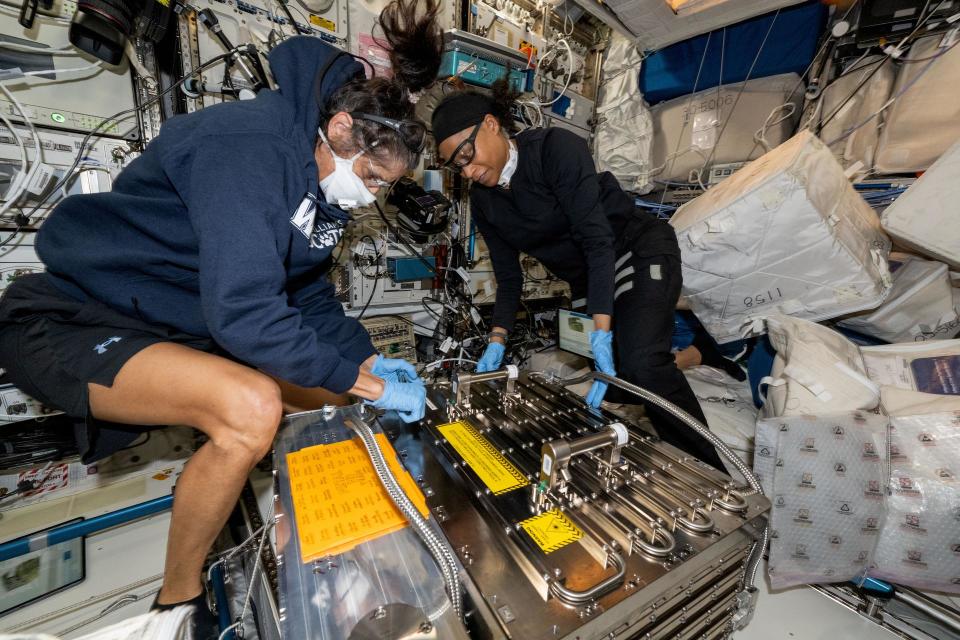

Researchers for that reason needed to adjust to function under these difficult problems, and the International Space Station offered the excellent setup. ESA’s steel 3D printer utilizes a stainless-steel cord thawed by an effective laser that gets to 2,192 ° F( 1200 ° C )to produce its liquified steel filament that obtains transferred layer-by-layer to develop out a preferred form.

Via painstaking examinations performed over numerous months, the group was lastly able to readjust the printer to its microgravity setting, creating the initial steel component precede this August 2024. The group intends to publish 2 even more things, after that all 3 will certainly be reminded Earth for high quality evaluation and future preparation.

Connected: Future moon astronauts might 3D-print their products making use of lunar minerals

” With the printing of the initial steel 3D form precede, ESA Expedition groups have actually attained a considerable landmark in developing in-orbit production abilities. This success, implemented by a worldwide and multidisciplinary group, leads the way for long-distance and long-duration goals where producing extra components, building and construction parts, and devices as needed will certainly be necessary,” stated Daniel Neuenschwander, supervisor of Human and Robot Expedition at ESA, in a statement.

This revolutionary innovation remains to increase its applications in the world, transforming areas such as medication, style, art, building and construction, food manufacturing and production. Precede, as long-duration goals to the moon and possibly Mars materialize, astronauts will certainly require a way of separately fixing or producing devices or components for equipment or frameworks that would certainly be tough to lug onboard a spacecraft, which have actually restricted ability.

As the innovation advancements, it might also eventually allow the printing of brand-new cells or body organs, improving the capacity to endure long-lasting area expedition– though we’re still years far from this being sensible.

Associated Stories:

— 3D-printed hearts on ISS can assist astronauts take a trip to deep area

— A BFF in Space! Bioprinter Will 3D-Print Human Tissue on the Space Station

— Best space-themed 3D prints: Recreate iconic spacecraft and objects

3D printers precede are absolutely nothing brand-new, as microgravity uses an intriguing setting for researchers to carry out experiments, establish much better 3D printing products, or produce frameworks tough to make in the world. Nonetheless, what’s substantial regarding ESA’s current statement is that this is the initial time a 3D printer has actually effectively generated a steel component.

This ability stands for a significant landmark as, till this factor, steel parts for area goals needed to be generated in the world and transferred to orbit– a pricey and intricate component of any type of goal.

Ferdja Ferdja.com delivers the latest news and relevant information across various domains including politics, economics, technology, culture, and more. Stay informed with our detailed articles and in-depth analyses.

Ferdja Ferdja.com delivers the latest news and relevant information across various domains including politics, economics, technology, culture, and more. Stay informed with our detailed articles and in-depth analyses.