-

Walmart is America’s grocery king, offering even more food than the following 2 biggest firms incorporated

-

The merchant is leaning greatly right into AI to obtain subject to spoiling foods to save racks also much faster.

-

Have a look inside among Walmart’s cutting edge warehouse for subject to spoiling products.

Walmart is the largest supermarket in the United States, with more shoppers getting their groceries there than from any kind of various other merchant.

To maintain the racks of its 4,600 United States shops well-stocked, the merchant depends on a substantial network of 42 local warehouse that obtain and arrange pallets of product.

On Wednesday, Walmart drew back the drape on among its cutting edge AI-powered cooled storehouses developed to manage subject to spoiling products like meat, dairy products, and generate.

The firm says it has actually finished 2 brand new builds, with 3 even more heading, while 5 existing subject to spoiling warehouse are being updated with the technology.

Have a look to see just how it functions:

Trucks get here with pallets that have of one kind of product

Getting here products are examined by human employees.

Forklift drivers placed getting here pallets right into a device that divides packages

Walmart states automation is enabling employees to shift right into higher-skilled functions.

The maker elevates the pallet and checks the materials …

” We understand what we possess, in what amount and where it is, done in close to live,” Dave Guggina, executive vice head of state of Walmart’s supply chain, informedCNBC “And we understand that at a degree of effectiveness that is substantially enhanced than what we have actually had the ability to attain with hands-on procedures or tradition software application.”

… and send out instances down a conveyor belt to be kept

The automation and monitoring enable Walmart to much better expect client need and maintain the correct amount of supply handy, the firm states.

What makes this center unique is that whatever needs to be cooled– similar to this lotion cheese

Walmart formerly revealed its automation modern technology at what are called “ambient” warehouse.

The racks get to as high as 80 feet and are accessed totally by robotics

Walmart states the extra upright area is enabling the firm to increase its gratification solutions for third-party vendors– like Amazon.

Storage facility workers watch on the circulation of product

This computerized stockroom still needs concerning 500 employees, with beginning pay at $ 20 to $34 per hour.

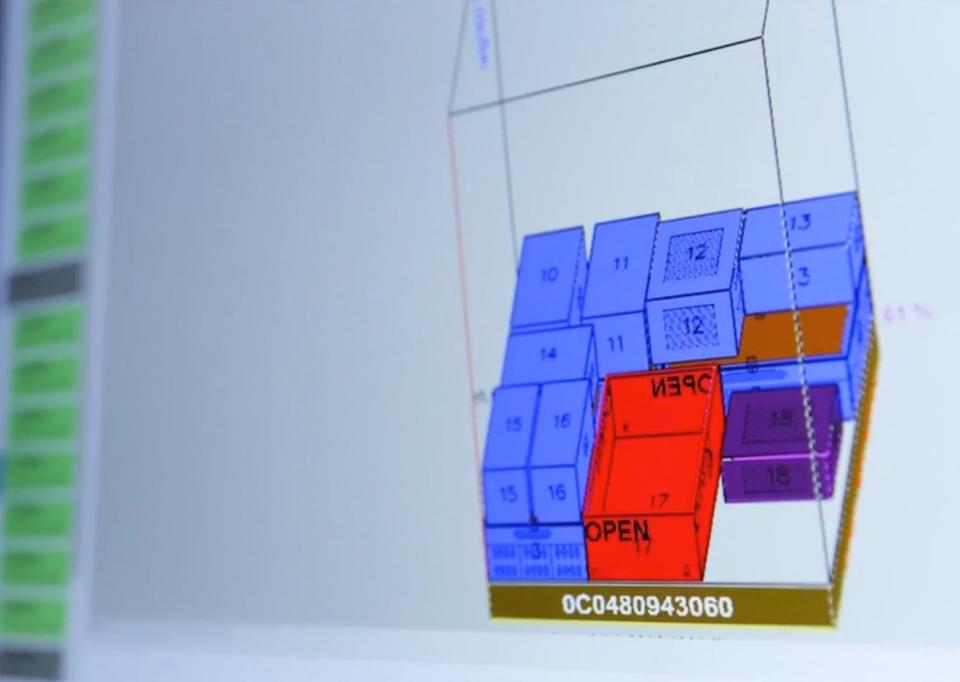

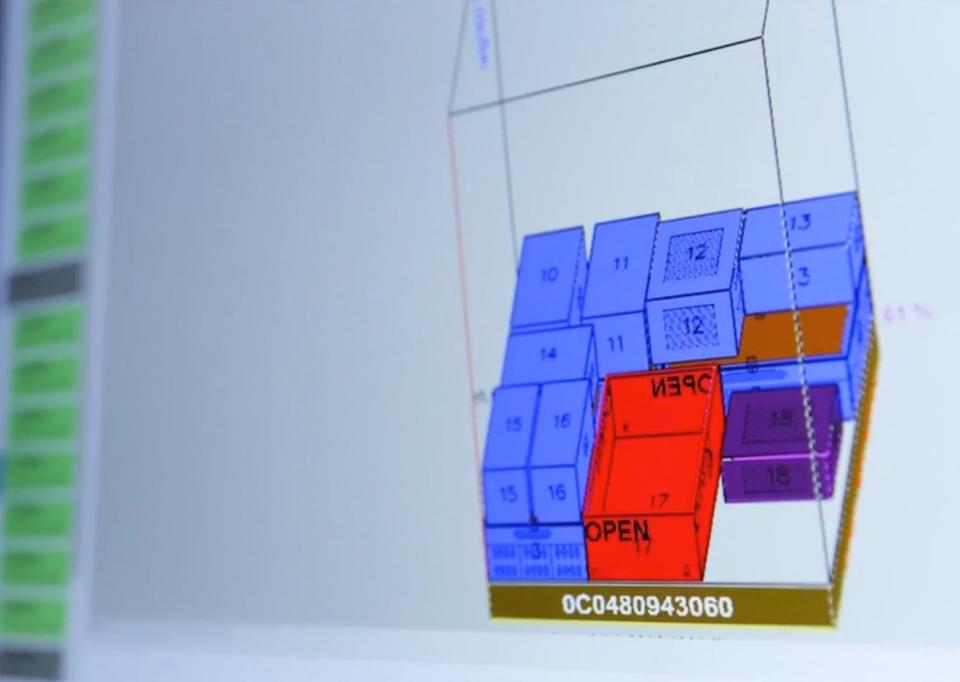

As shops report supply demands, an AI formula figures out one of the most reliable means to load the mix of items they require onto a brand-new pallet

The system additionally places even more delicate products, like eggs and fruit, towards the top of the pile.

Walmart states the version attempts to make certain that pallets are filled in such a way that streamlines the restocking procedure for shop workers

The system understands specifically which aisle in a certain shop that a team of instances is headed to.

Robots after that draw the products from throughout the stockroom

” You take a warehouse today, among our affiliates is walking up to 10 miles a day, raising hundreds of extra pounds, relocating pallets and points like that,” Walmart CFO John David Rainey stated of the typical, non-automated system.

Chosen product streams to a filling location …

Brand-new building is slated for Wellford, South Carolina; Belvidere, Illinois; and Pilesgrove, New Jacket.

… and is filled onto a pallet according to the strategy, prior to it is covered for delivery

Guggina informed CNBC some pallets can be piled specifically with products for satisfying ecommerce orders, instead of being placed on racks.

It’s a complicated system that still needs human oversight

Of Walmart’s 42 warehouse, CFO John David Rainey said the firm has 15 with “some degree of automation.”

Completed pallets are after that filled onto a vehicle and sent out to a shop

The 15 computerized warehouse offer concerning 1,700 shops.

At the shop, employees dump the vehicles and replenish the racks

If whatever goes according to strategy, replenishing the racks relocates faster.

Walmart states its computerized storehouses can refine two times as much product as typical ones

” When we automate among these DCs, we see about twice the throughput with half the headcount,” CFO John David Rainey stated. “Therefore the mathematics on this is extremely, extremely engaging.”

Review the initial short article on Business Insider

Ferdja Ferdja.com delivers the latest news and relevant information across various domains including politics, economics, technology, culture, and more. Stay informed with our detailed articles and in-depth analyses.

Ferdja Ferdja.com delivers the latest news and relevant information across various domains including politics, economics, technology, culture, and more. Stay informed with our detailed articles and in-depth analyses.